Turbocharger Not Working?

A failed turbocharger can be much more than just an internal issue, the turbo failure may have occurred due to external issues. Turbochargers are designed to operate in very specific tolerances that don’t leave much room for variation. Failures can occur for a number of reasons from metal fatigue to overheating and physical damages caused by external debris.

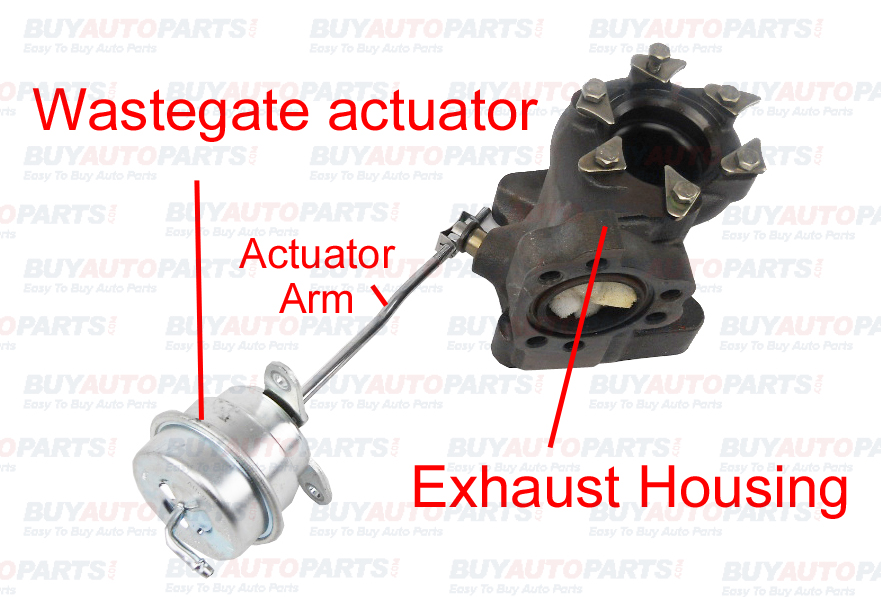

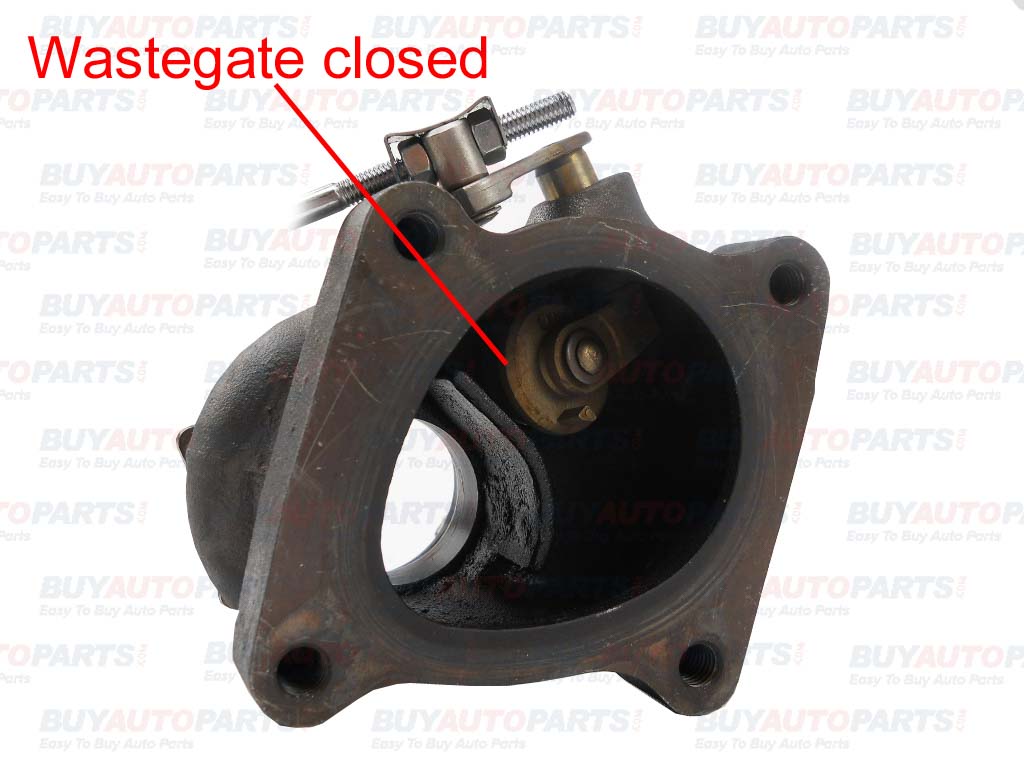

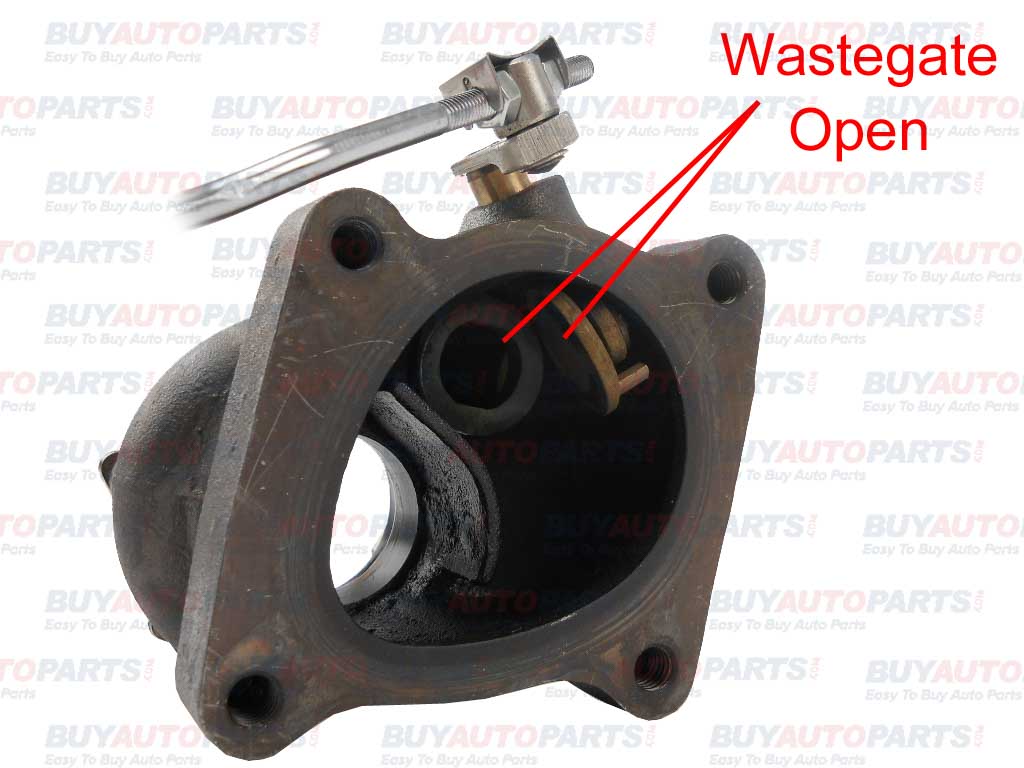

Step 1: Check the exhaust housing to see if the wastegate door is stuck open or closed.

|

|

|

|  |

The exhaust housing or rear section of a turbocharger (pictured above) houses many parts of the turbo that control the boost levels. The Turbine wheel which is moved by the exhaust gases is located here as well as the wastegate if the unit has an internal wastegate. Failures do not generally occur in the exhaust housing involving the turbine, but can happen involving the wastegate door. The wastegate can become stuck open or closed which will cause issues with the boost levels of the turbo. When the door is stuck open it will cause all the pressure to be released and the turbo cannot create boost. On the other hand if the door is stuck closed it can cause over boosting due to the units inability to release pressure between shifts. Both of these issues can be incorrectly diagnosed and sometimes can be fixed by adjusting the wastegate actuator |

Step 2: Check the oil lines and bearings in the center housing for damage.

|

|

The center housing of a turbocharger may be the smallest part of the turbo but is easily the most important. All of the bearings and oil lines are run through this section which means that if there is an issue here, it spells trouble. The bearings sit in this center section and are cooled by oil that runs through the unit and in some turbos coolant as well. With the oil flow restricted or stopped for even a faction of a second, the bearings will fail due to overheating. This section is also where the shaft is housed, riding on the bearings and relying on oil flow as well. Many failures that are blamed on manufactured defects can be tracked back to this section once the unit is disassembled. |

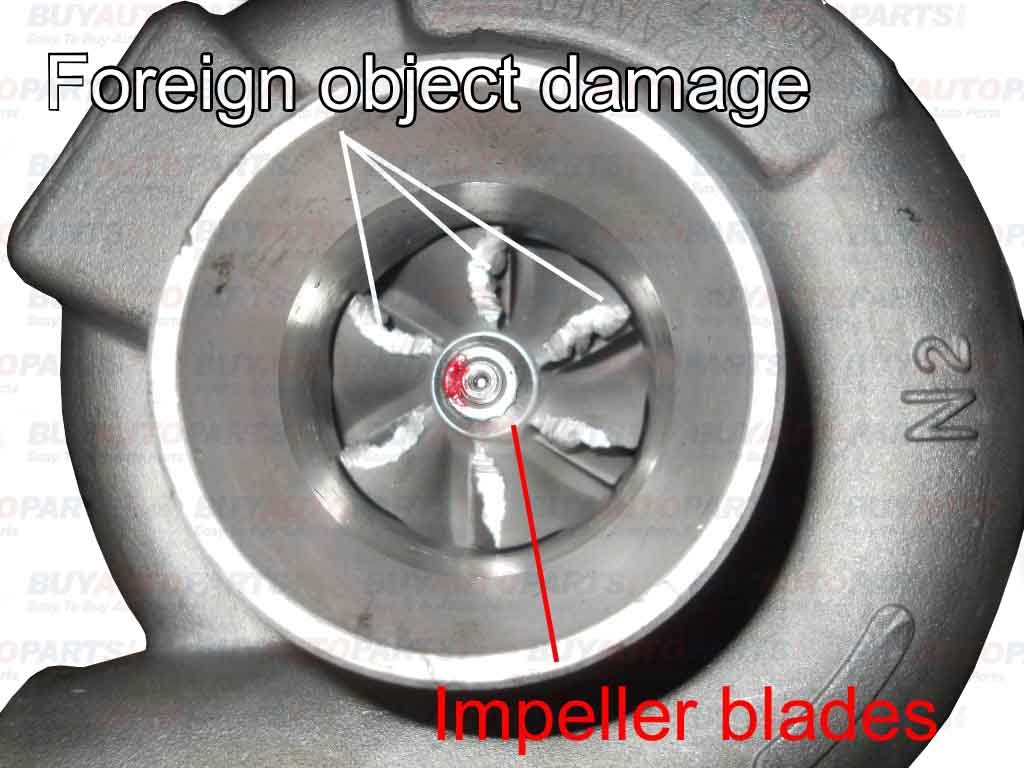

Step 3: Check the impeller blades for foreign object and debris damage.

|

|

Foreign objects can enter an intake system in many forms sometimes they are as small as dust particles and others as large as rocks. The smaller debris will usually pass through the motor with no issues but can become harmful if allowed to build up. If small debris is entering the system the air filter may need to be changed or there is an opening in the intake system. Larger debris such as rocks and bolts that may be dropped into the intake system will impact the blades causing complete failure of the turbo. This damage can be seen very clearly on the blades of the impeller. |

Step 4: Check the oil flow to the turbocharger for oil starvation or oil restriction

|

|

Oil starvation is the number one cause of failure on turbochargers, not only is it the cause of the original failure but it can cause repeat failure as well. Oil starvation is when the oil flow to the turbocharger is restricted in anyway. All the components in a turbo spin at velocities so high even a fraction of a second of oil starvations can cause huge amounts of damage. When the oil flow is restricted it causes a lack of cooling as well as a lack of lubrication for the bearings in the center section of the turbo. The bearings begin to overheat which damages them and they begin to wobble. Once a bearing begins to wobble it is ruined, the turbo will need to be rebuilt or replaced. Oil starvation can be caused by a blockage in the oil system but can also be caused by sludging. Oil sludging is created by oil that overheated and began to burn in the oil lines near the turbo. Oil sludge can settle in the oil pan and if it gets pulled though the oil lines it can slow the flow of oil to the turbo. Turbos that are starved of oil are not covered by warranty and the failure will continue until the restriction is removed. |

Step 5: Check the turbocharger for metal fatigue.

Just like any other auto parts turbochargers will only last if they are properly taken care of. Any part will fail with lack of maintenance but a turbo is particularly fragile due to its nature. The only true turbo failure is metal fatigue which is caused by the metal in the turbo becoming fragile due to heat cycling thousands of times. The unfortunate fact is that a turbocharger has an average life span of about 80 – 120K miles. On a diesel motor that life span can be closer to 4 times that but still the turbo will eventually fail. When the turbo does fail be sure to check for a cause before replacing the unit, otherwise it could cost much more than expected.